When it comes to modern technology, controlling electrical currents is essential to ensuring everything runs smoothly. If currents become too high, components may overheat, break, or the system could crash. That’s where a resistor comes into play. These simple, passive components help manage and limit the flow of current, preventing overload and providing a reliable solution.

To better understand resistors, we will break down each section, explore the various types available, and help you grasp the roles they play in different electronic applications. Whether you’re seeking precision control, temperature sensitivity, or surge protection, understanding these resistor types is key to solving current-related issues in circuit design.

Outline

ToggleWhat Is Electrical Resistance?

In this section, we will learn about electrical resistance and explore the materials used in a resistor.

Electrical resistance can be defined as the obstruction of the flow of electrons through a conductor. In this case, the conductor is the resistor, which can be made from several materials such as glass, mica, rubber, and wood.

To calculate electrical resistance, we use the unit Ohm (Ω) and the following formula:

V = IR

Where:

- V = Voltage

- I = Current

- R = Resistance

Ohm’s Law states that the current flowing through a conductor is directly proportional to the voltage applied across it and inversely proportional to its resistance. In simpler terms, the more voltage applied, the more current flows through. However, a thicker conductor offers less resistance to the current.

All About Resistors

What Is A Resistor?

Since we’ve covered the basics of electrical resistance, let’s take a closer look at what a resistor is, why it’s used, and where it should be applied.

A resistor is a passive electronic component designed to introduce a specific amount of resistance into a circuit. Typically, it consists of a resistive material wrapped around a ceramic or glass core. The ends of the resistive material are connected to two leads, which are then attached to a circuit.

Resistors work by causing electrons to collide with the atoms of the resistive material, preventing some electrical energy from being converted into heat energy. This results in a voltage drop across the resistor.

Now that we understand what a resistor does and how it works, you might be curious about its various applications. While resistors are primarily used in electronic circuits, here are a few examples of their versatility across different applications:

- Limit Current: Introducing a resistor into a circuit helps control the amount of current flowing through it.

- Divide Voltage: Resistors can be used to divide voltage into smaller components.

- Set Time Constraints: In circuits involving capacitors or inductors, resistors help determine the circuit’s time constant, affecting its response to input signal changes.

- Provide Heat: In devices like heaters and toasters, resistors convert electrical energy into heat.

Classifications Of Resistors

Here we will explore the different classifications and types of resistors available and understand each of its unique abilities and features.

Despite resistors being available in different shapes, sizes, and materials, resistors are classified into two main groups, which are:

Linear Resistors

These types of resistors cause a voltage drop whenever current flows through them. They maintain a consistent relationship between the voltage and current and have an increased tolerance of about 20 percent. Any changes in temperature and voltage can cause the value to shift.

They’re further divided into two subtypes:

- Fixed Resistors: This type of resistor has a specific value that can’t be changed and is widely used.

- Variable Resistors: In contrast, these are adjustable and have values that can be changed through a tactile medium like a dial or knob.

Non-Linear Resistors

Unlike linear resistors, current flows through it, and the changes are applied by temperature or voltage. Additionally, non-linear resistors do not change according to Ohms law.

Different Types Of Resistors

Precision Resistors

The precision resistor stands out for its stability and high accuracy in resistance values, often within tight tolerances of ±0.01% to ±1%, and falls in the Liner and fixed resistor categories. They are ideal for circuits that require consistent performance and low error margins, especially in medical and laboratory device

Additionally, depending on the application, these resistors handle low to medium, power ratings ranging from 0.1W to 1W. Materials that minimize temperature coefficients ensure a minimal change in resistance over varying temperatures. Such resistors reduce the need for frequent recalibration, making them a cost-effective solution for high-performance electronic systems.

Thin-Film Resistors

Characterized by a highly accurate resistive layer of vapor deposited material on an insulating surface, the thin film resistor is typically made up of glass or ceramic and is a few nanometers thick. This allows for a highly controlled resistance value, making them suitable for applications in audio electronics, measurement devices, and high-frequency circuits.

The thin-film resistors offer excellent stability over time and temperature, with a low-temperature coefficient of resistance (TCR), ensuring a consistent operation even under fluctuations. This allows for fine adjustments in resistance values during production, which ensures their accuracy in demanding electronic applications.

Thick Film Resistors

Thick film resistors differ from their counterparts primarily in the method of applications and material thickness a paste is made out of conductive material and is printed onto a ceramic base, resulting in a much thicker film which is measured in microns. These offer higher power ratings up to 2W and are more affordable making them widely used in consumer electronics and automotive applications.

However, they exhibit a higher temperature coefficient of around ±100 ppm/°C, which means their resistance varies more with temperature changes. While not as precise as thin film resistors, thick film versions excel in high-power applications due to their robust construction and higher power tolerance for thermal stress.

Wirewound Resistors

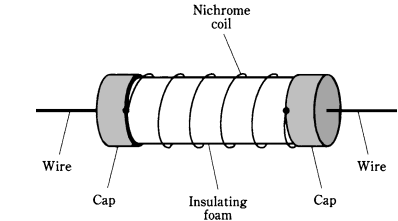

Source: Wire Wound Type Resistors

Wire wound resistors are constructed by winding a metal wire usually made of alloys like nickel-chromin or tungsten, around a ceramic or fiberglass core. This design allows for the wire’s diameter and length to determine the value. Wireound resistors are highly durable and can operate under extreme temperatures without any significant changes in resistance.

Their excellent heat dissipation makes them suitable for power supplies, motor controllers, and other high-current applications. Despite their bulkier size, wire-wound resistors are valued for their reliability, low noise, and minimal tolerance variations which fall within ±1%.

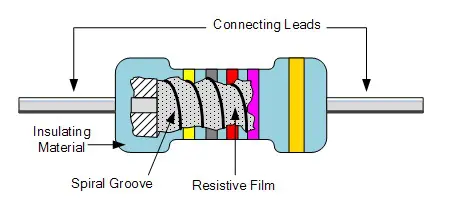

Carbon Film Resistors

Source: Film Type Resistors

Produced by depositing a layer of carbon upon a ceramic substrate, these affordable resistors have widespread use. Often found in general-purpose electronic devices like radios and televisions. The carbon film resistor provides temperature stability, with a temperature coefficient of ±200 ppm/°C.

These resistors fall in the liner and fixed category of resistors and can handle power ratings of 0.125W to 2W, making them suitable for low- to medium-power applications. Carbon film resistors also provide good noise suppression, though not as effectively as metal-based resistors, and are resistant to environmental factors such as humidity.

Metal Oxide Resistors

The metal oxide resistor creates resistance using a thin layer of metal oxide like tin oxide. It is then deposited upon a ceramic rod. This methodology enhances the temperature stability and increases the power rating, going up to 5W. Metal oxide resistors are often valued for their ability to withstand higher voltages and extreme temperatures.

This makes them suitable for industrial equipment and high-power circuits. It has a temperature coefficient of around ±300 ppm/°C. Additionally, they are classified as liner and fixed resistors and are more resistant to corrosion than carbon-based resistors, ensuring long-term reliability in harsh environments.

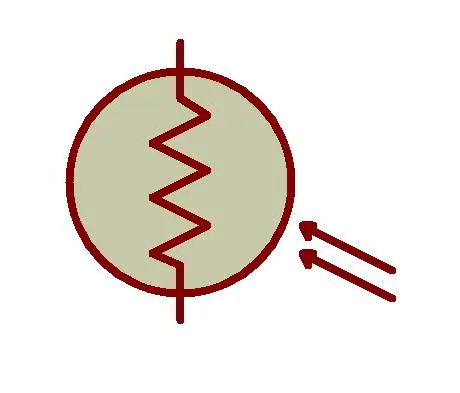

Varistors

Source: Varistor

Varistors, also known as voltage-dependent resistors, exhibit a unique property where their resistance changes significantly with the applied voltage. At low voltages, the resistance is high, but as voltage increases, the resistance drops dramatically, protecting circuits from voltage surges. Varistors are often used in surge protectors, power supplies, and lightning protection systems.

These components are typically made from metal oxide materials and can handle high power ratings, up to several hundred watts. The clamping voltage, where the resistance starts to drop, varies depending on the design, but common values range from 10V to 1000V. Varistors are highly effective in protecting sensitive electronics from transient voltages caused by power surges or lightning strikes.

Magneto Resistors

Magneto resistors change their resistance in response to a magnetic field, making them ideal for sensing applications. These resistors are often used in automotive systems, such as anti-lock braking systems (ABS), and in industrial equipment to detect position or speed. The resistance change is proportional to the strength of the magnetic field, allowing for precise measurements.

Magneto-resistors are typically constructed using semiconductor materials, such as indium antimonide or permalloy, Their temperature stability and low noise make them reliable in harsh environments, and power ratings are generally low, around 0.1W to 0.5W. These resistors are crucial for applications requiring contactless sensing and high reliability.

Thermistors

Thermistors are temperature-sensitive resistors whose resistance changes dramatically with temperature. Two types exist: Negative Temperature Coefficient (NTC) thermistors, where resistance decreases as temperature increases, and Positive Temperature Coefficient (PTC) thermistors, where resistance increases with rising temperature.

Thermistors are widely used in temperature sensing, such as in HVAC systems, automotive temperature monitors, and consumer electronics. NTC thermistors are preferred for precise temperature measurements, while PTC thermistors are often used in circuit protection, as the increased resistance can limit current flow in over-temperature conditions.

Light-Dependent Resistors (LDRs)

The light-dependent resistor exhibits a change in resistance based on the intensity of light, as the intensity increases, the resistance decreases. Making them useful for light-sensitive applications like automatic lighting, solar trackers, and camera light meters. Alternatively, they are also called photoresistors because they are made up of a semiconductor material called cadmium sulfide, which reacts to photons.

The light-dependent resistor exhibits a change in resistance based on the intensity of light, as the intensity increases, the resistance decreases. Making them useful for light-sensitive applications like automatic lighting, solar trackers, and camera light meters. Alternatively, they are also called photoresistors because they are made up of a semiconductor material called cadmium sulfide, which reacts to photons.

These harness a power time of around 0.1 W to 0.5W. Although the response time depends upon the light conditions, LDRs are valued for their ease of use, affordability, and effectiveness in light-sensing tasks.

Fusible Resistors

Fusible resistors combine the functions of a resistor and a fuse, designed to limit current under normal conditions and open the circuit in case of an overload. These resistors are commonly used in power supplies, televisions, and other electronic devices that require protection from short circuits or excessive current.

Fusible resistors are constructed from materials that can withstand heat for normal operation but melt under high currents, breaking the circuit. Power ratings can vary from 0.5W to 5W. Once the resistor “blows,” it must be replaced, similar to a fuse, ensuring the protection of sensitive components in the circuit.

FAQs:

Resistors can be made from various materials such as glass, mica, rubber, wood, and ceramic. These materials determine the resistor’s properties, including its resistance value and heat dissipation.

Resistors limit the flow of current by causing collisions between electrons and atoms within the resistive material. This reduces current and can create voltage drops, influencing circuit behavior.

Resistors are mainly classified into linear (fixed and variable) and non-linear types. Linear resistors maintain a constant relationship between voltage and current, while non-linear resistors’ resistance changes with voltage or temperature.

Resistors are used to limit current, divide voltage, set time constraints, and provide heat. They’re essential in devices like power supplies, heaters, and voltage regulators across various electronic circuits.

Conclusion

We hope this guide provided valuable insights into the different types of resistors and their various applications. Whether you’re designing circuits for precision, temperature control, or voltage regulation, understanding the role of each resistor type is essential for success. Did you find the details useful? Feel free to reach out with any questions or for more information!

One Response

thank you so much I am so happy